AJS Production: the alchemy of high precision and laser innovation

In the heart of the Jura canton, AJS Production embodies excellence in subcontracting for high-precision laser engraving for luxury watchmaking. By integrating Laser Cheval’s Quartz Géode technology, the company did not simply acquire an additional tool — it transformed its production model.

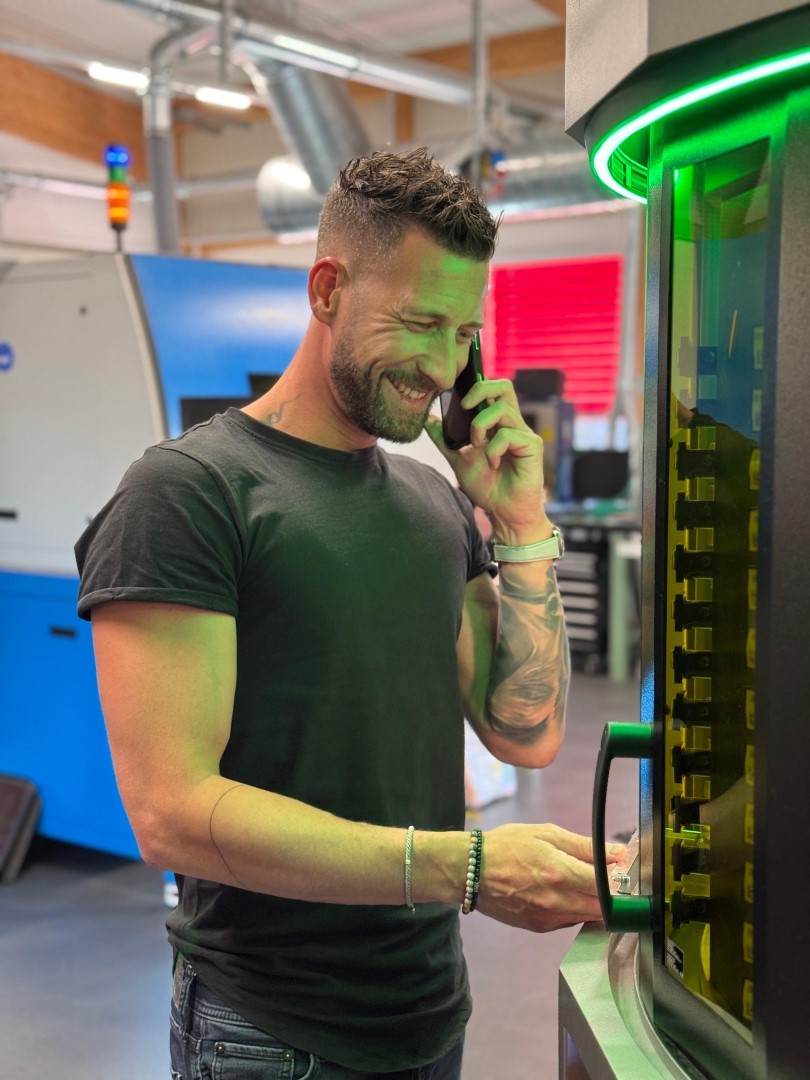

Jérôme Péré, Director of Operations and Innovation, takes us behind the scenes of this technological revolution where the micron reigns supreme.

A technological transition driven by excellence

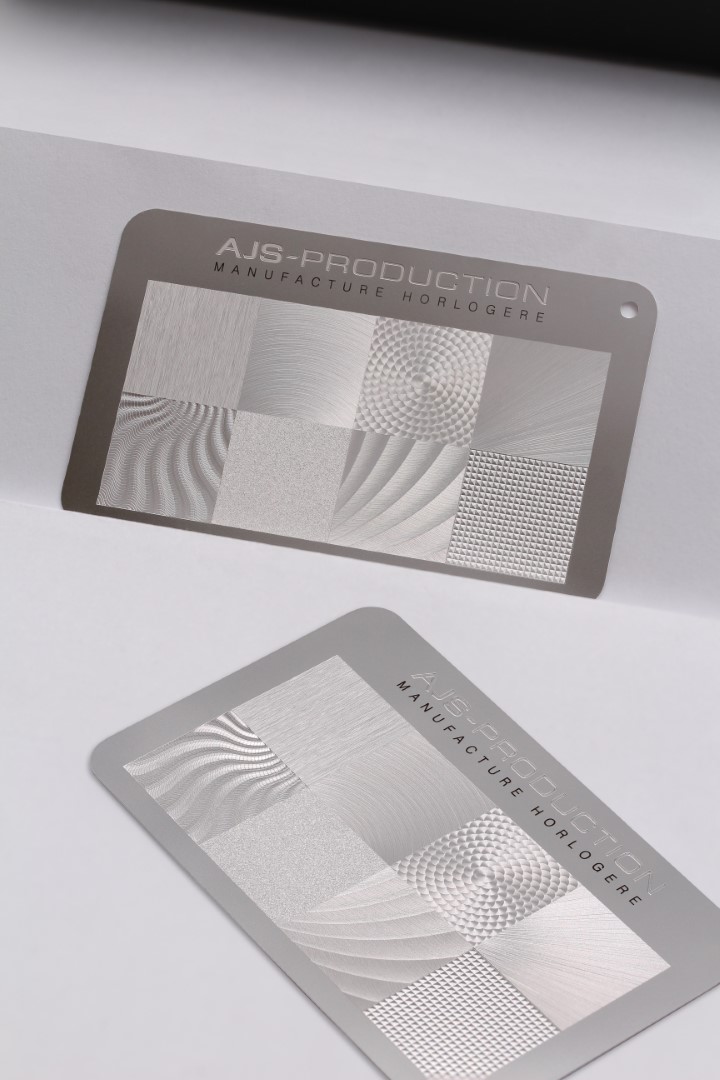

For AJS Production, technological evolution is not an option — it is a necessity driven by client demands and passion for the craft. Although the Swiss company historically uses nanosecond fiber lasers in production, it made a major shift in 2020 toward femtosecond technology. The reason? To support developments in the high-end watchmaking sector, which is increasingly demanding in terms of aesthetics and finishing quality. To achieve these objectives, AJS Production relies on the expertise of Laser Cheval, based in Marnay in the Franche-Comté region, a company with more than fifty years of experience in manufacturing laser machines. With the Quartz Géode, the latest addition to its range and a concentration of technology, the company has gained a head start in industrial laser use. AJS Production closely follows these developments and quickly recognized the full potential of Quartz Géode and femtosecond technology, as Jérôme Péré explains. “With nanosecond lasers, the material is reheated, which inevitably creates burrs or slag that then have to be removed mechanically or chemically.” Femtosecond technology, however, produces no burrs. Why? “We achieve what is called cold ablation. We no longer heat — we pulverize the material. This allows us to work on components whose surface condition is already finished, such as polished parts or extremely fragile terminations, without altering their original shine. It’s ‘zero defects’ right out of the machine.”

Quartz Géode: An architecture designed for the micron

The choice of the Quartz Géode was no coincidence. Beyond the machine’s execution speed and precision, its very design attracted the company. While most laser machines on the market use a moving gantry (the laser head moves above the part), Laser Cheval took the opposite approach with Quartz Géode. The head remains fixed, and the table supporting the parts moves along the X and Y axes.

This design detail radically changes the game in terms of metrology. “Mechanically, stability is total. On older systems, tolerances sometimes fluctuated around 0.04 mm. With Quartz Géode, we regularly go below 0.02 mm,” notes Jérôme Péré. The machine’s stability is such that it requires virtually no recalibration. For AJS Production, this engraving precision is not a luxury — it guarantees repeatability in complex series where each part must be strictly identical to the previous one.

Mastering image acquisition: 3 light sources, 3 cameras, and advanced software — nothing less!

One of the major challenges in micro-engraving lies in part positioning. How can perfect centering be ensured on a component that shines like a mirror? The answer lies in the machine’s optical intelligence. Quartz Géode integrates a backlighting system beneath the table. “This is the crucial point,” insists the quality manager. “On a polished part, top lighting creates reflections that mislead the centering cameras. By turning off the upper lights and illuminating from below, the part appears as a perfect black silhouette against a bright background. The contour becomes absolutely sharp for the recognition algorithm. We literally halved our centering error margins.”

Autonomy as a growth driver

AJS Production has embraced full automation to ensure continuous day-and-night production. Quartz is paired with Géode, a 48-tray palletizer. The machine can therefore handle multiple series without human intervention. “The idea is for the machine to work even when we are not there — at night, on weekends, during holidays,” explains Jérôme Péré. “We can load 48 different trays and schedule different programs.” This autonomy can be remotely supervised. Thanks to a secure connection and internal cameras, technicians can monitor and control production from outside the facility, ensuring cycles run smoothly. “We can launch as many series as there are trays — the machine switches between programs and tray types. Knowing I can start production on Friday and find it completed and compliant on Monday morning is incredibly reassuring.”

“Structural projection”: a patent for the future

The relationship between AJS and Laser Cheval goes beyond a simple commercial partnership — it is a true R&D collaboration. This cooperation led AJS to file an innovative patent on structural projection.

The concept is revolutionary for watch decoration. It involves applying successive layers of technical paint, then using the laser to selectively ablate these layers until the desired effect or pattern is achieved. It is an ultra-high-precision process. “The principle is to carve into the layers to reveal colors or create reliefs of a fineness that traditional printing cannot reach. It’s a fusion between materials chemistry and laser precision. Femtosecond technology can even fool a connoisseur’s eye by faithfully reproducing traditional watch decorations. The goal with laser technology is no longer just to copy, but to produce complex decorations in areas that cannot be accessed mechanically. Femtosecond technology has allowed us to reach a level of brilliance that delivers a breathtaking result.”

Toward a hybrid and customized laser source

AJS Production is not resting on its achievements. The company is already working on optimizing laser sources. Quartz Géode can integrate high-power sources up to 40 Watts. Currently, Light Conversion 40-Watt sources allow not only faster execution but also pulse duration modulation — even switching to nanosecond mode when needed, since controlled material heating also has its advantages.

The laser: a tool of freedom in precision industrial creation

For Jérôme Péré, the laser has become the most versatile tool in the workshop. “There are no longer any limits linked to tool wear or the mechanical resistance of a drill. The only limit is our imagination and the machine’s ability to translate our CAD files into physical reality. These advances have forced us to push the boundaries of CAD design beyond traditional systems.”

By combining the Swiss rigor of AJS Production with the French engineering expertise of Laser Cheval, Quartz Géode stands out as a new standard of Industry 4.0 manufacturing. An alliance where technology creates emotion through innovative, precise, and perfectly finished watch components.

For Jérôme Péré, the laser has become the most flexible and precise production tool on the market. By mastering laser technology, the Swiss company continues redefining microtechnical decoration standards. “Today, we no longer ask whether a particular engraving is possible — we ask how we’re going to do it with Quartz Géode,” he concludes. A clear message for a watchmaking industry in constant pursuit of perfection and attention to detail.