Laser welding, an innovative high precision technology

The laser is a highly efficient, sophisticated and widely used production tool to meet the challenges of industry. Of its uses, marking and cutting are the most widespread. Laser Cheval, your partner in laser services, also offers laser welding. Here is an overview of this method, which has both technical and economic advantages.

How does laser welding

How does it work?

Laser welding is a process that allows several metal parts to be joined together with a targeted supply of heat, using a laser. The laser is a particularly concentrated source of heat, allowing welding on narrow surfaces, on simple or complex shapes, with total control of the penetration depth. Thanks to the high energy density of the laser, the areas fuse and are welded together by cooling.

What are the laser welding methods?

There are three methods:

Spot laser welding

Spot welding is based on a pointing operation to join the two parts together. Laser welds emit several pulses per second.

Laser welding with a bead

This involves making a metallurgical connection from point A to point B with a continuous and completely sealed weld seam.

Transparent laser welding

This is used for laser welding of polymers. This process allows for the production of thin, airtight welds.

What metals are compatible with with laser welding?

Many metals can be joined by laser welding :

- Metals: steel, titanium, stainless steel, aluminium, copper, etc.

- Precious metals: gold, silver, etc.

- Alloys: inconel, kovar, etc.

What are the advantages of laser welding?

Laser welding is very reliable. It allows for the production of highly resistant assemblies. Here are the other advantages:

- Guaranteed tightness

- Increased performance and speed

- Increased quality and precision without distortion of the part

- Compatibility with different materials

- Work on simple and/or complex shapes

- Can be automated

- No mechanical stress

- Economical method reducing production costs and without material input

What are the areas of application of laser welding?

Laser welding is a cutting-edge technology that can be used for a large number of applications in sectors as varied as the automotive, aeronautical and jewellery industries, which have specific cleanliness requirements. The advantages of laser welding are also interesting for the medical field, particularly in the manufacture of implantable medical devices.

A laser welding project? Call on Laser Cheval, your expert partner!

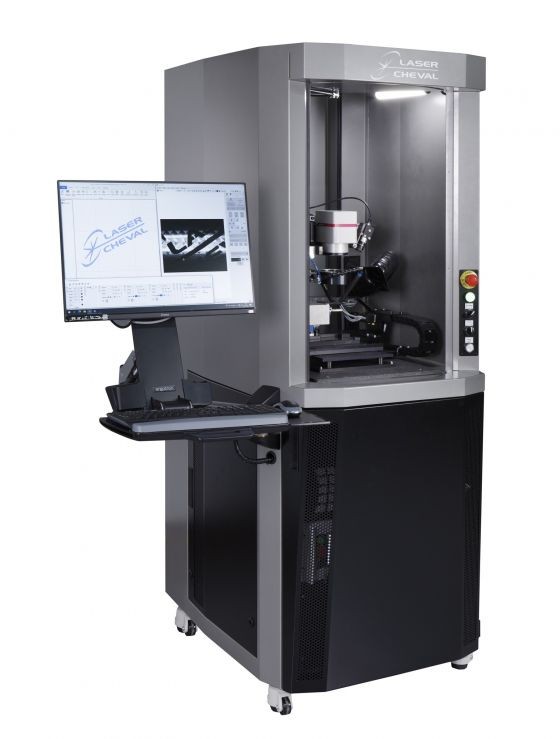

Do you have a specific request? Would you like to check the feasibility of your project and move towards laser welding? Whatever your questions, Laser Cheval is at your disposal to advise you and accompany you in the best conditions. Laser Cheval has a range of jigs and machines controlled by software. To meet your specific requirements, Laser Cheval can design a suitable machine.

Contact us on +33(0)3 81 48 34 60 or by e-mail laser@lasercheval.fr